Industrial Temperature Control Solutions

Your one-stop solution: design, frame construction, switch cabinet construction, programming, spray finishing, plant construction and plant testing in one location – offering high vertical integration.

Our Solutions

Temperature control units for water

autotherm temperature control units for water are used in various fields of industry, research and laboratory applications.

Temperature control units supply mold tooling, tanks, open baths, double-walled containers, heat exchangers and heating chambers with tempered water, maintaining consistent temperatures with high precision.

Temperature control units for thermal oil

autotherm temperature control units for thermal oil are used in various fields of industry, research and laboratory applications.

The temperature control units are specially designed to supply a wide range of applications, such as tooling, calender and coating rollers, double-walled containers, heat exchangers and heating chambers, with precisely temperature-controlled thermal oil. Their main function is to maintain a precise and constant temperature ensuring optimum operating conditions.

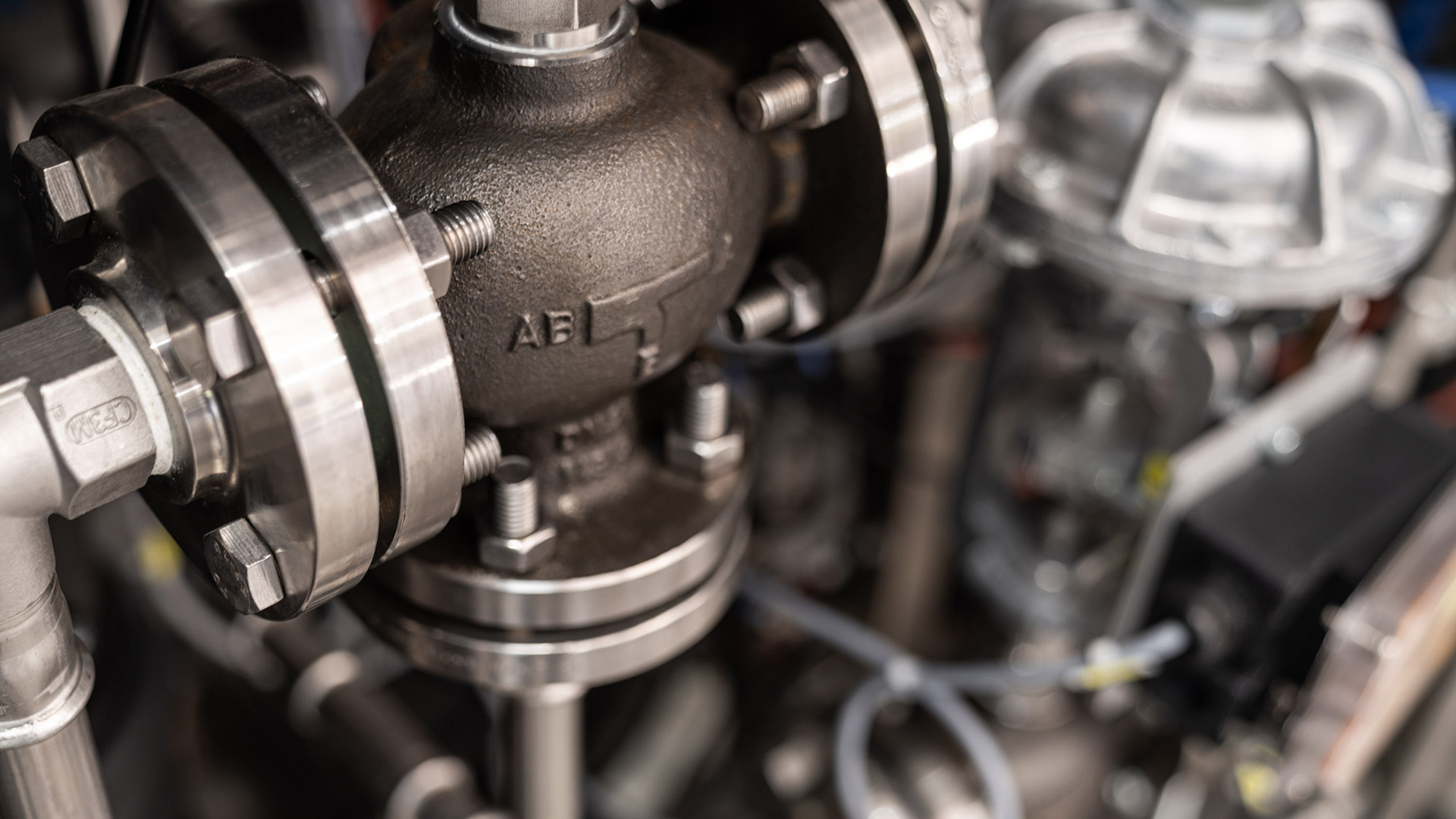

Conditioning Systems

autotherm conditioning systems are specialized in precise regulation of temperature, flow and pressure of liquid media such as water, ethylene-glycol-based coolants, oils or brines.

Our conditioning systems are mainly used in the automotive parts testing field, to environmentally stress-test various components such as batteries for electric cars, gearboxes, motors and power electronics running defined flow rates and temperatures using heat transfer medium.

Cooling and Tempering Tunnels

autotherm tempering tunnels are specially designed for temperature management of metal and plastic components. These components are moved continuously through the tunnel on conveyor belts.

Inside the tunnel, the components undergo targeted temperature adjustment, with heat being extracted or added as required. The individual adjustment of the tempering tunnels, including the control of temperature, heating and cooling system performance, tunnel geometry and belt speed, is carried out precisely in accordance with the specific requirements of the respective tempering task.

Special Systems Construction

Thanks to our extensive expertise and high vertical range of production at our Bad Königshofen site, we offer an exclusive complete solution from a single source. Our services cover the entire process – from planning and design, frame construction, switch cabinet construction and programming, spray painting, through to the final installation and testing of the systems.

Service

Maintenance

Routine inspections and scheduled maintenance ensure the reliable and safe operation of your temperature control units, conditioning systems, chillers, and cooling tunnels.

Repair

autotherm systems win over customers worldwide with their exceptional quality, durability and reliability. Still, depending on where a machine is used and how many hours it runs, some components may wear out. Our repair service is ready to help you out quickly and efficiently.

Calibration

Entrust the calibration of your equipment to our skilled experts. We guarantee comprehensive specialist competence to calibrate your equipment with precision.

Commissioning

On initial commissioning, we ensure professional installation and guarantee that your autotherm units are ready for operation. Our team of experienced service technicians will review your systems and adapt them to the specific conditions at your site.

Across all industries, our customers can rely on our highly integrated production process. Made in Germany and at a single location, we provide: design, frame construction (to avoid fixed sizes), customised paint finishes, switch cabinet construction, programming, plant construction and plant testing.

The one-stop solution that allows us to respond flexibly to modification requests – often long after the project has started.

autotherm has been a partner to these industries for over 55 years:

- Machine tools and mold making

- Welding and cutting technology

- Laser technology

- Automotive industry

- Plastic industry

- Packaging and printing industry

- Food, chemical and pharmaceutical industry

- Medical and laboratory technology

Branches

Trade Shows & Events

Grabfelder Jobmeile (Job Fair)

on February 22, 2026

in Bad Königshofen

Automotive Testing Expo Europe 2026

from 23 to 25 May 2026

in Stuttgart

Fakuma

International trade fair for plastics processing

from 12 to 16 October 2026

in Friedrichshafen

News

16.01.2025: Sponsorship: Renovation of the TSV Bad Königshofen Locker Rooms

29.08.2024: Visit us at Fakuma from October 15 to 19, 2024, in Friedrichshafen!

Carreers

Do you want to help develop innovative temperature control solutions for global clients at a market-leading company?

About us

Our long-standing expertise in the global market and across diverse industries promises one thing: absolute reliability and consistently flexible, fast implementation of your requirements in temperature control solutions.